Shelves as Tray Freeze Drying

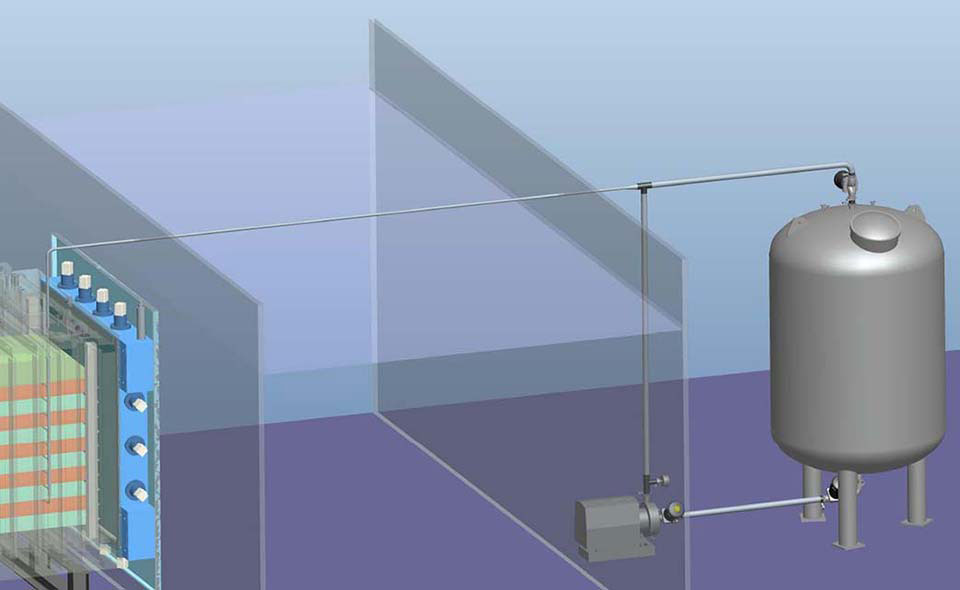

The API is distributed to each shelf in ration by using tube where sanitary flowmeter have been used to ensure accurate ration. The whole process is completed in full-closed system to reduce the risk of contamination(Unnecessary to open the gate of freeze dryer when loading). The materials are loaded to shelves directly to ensure better heat transfer, as a result, the freeze cycle is shortened and the cost is reduced.

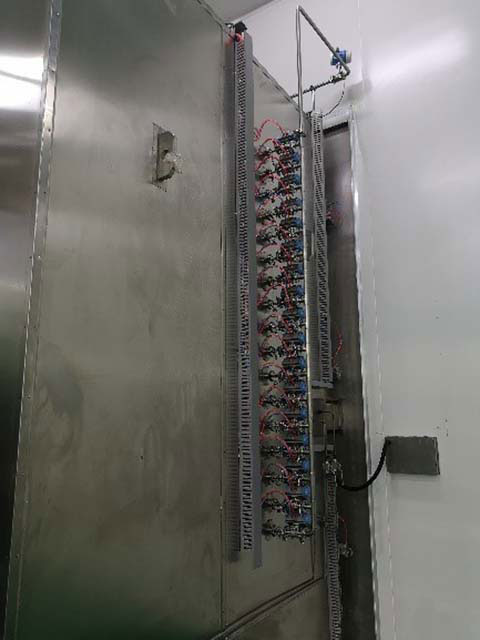

Loading System

The system adopts close feeding or automatic manipulator to realize feeding for each shelf with quality flow meter and control system.

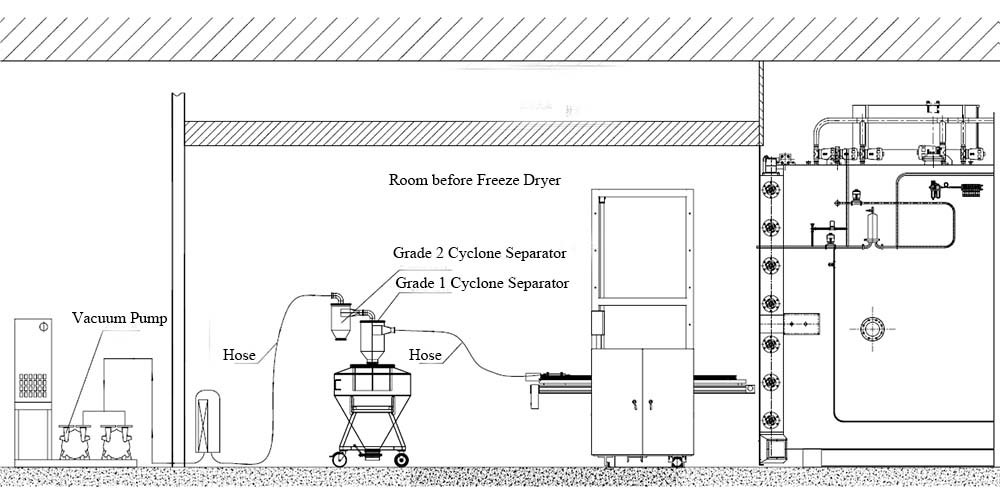

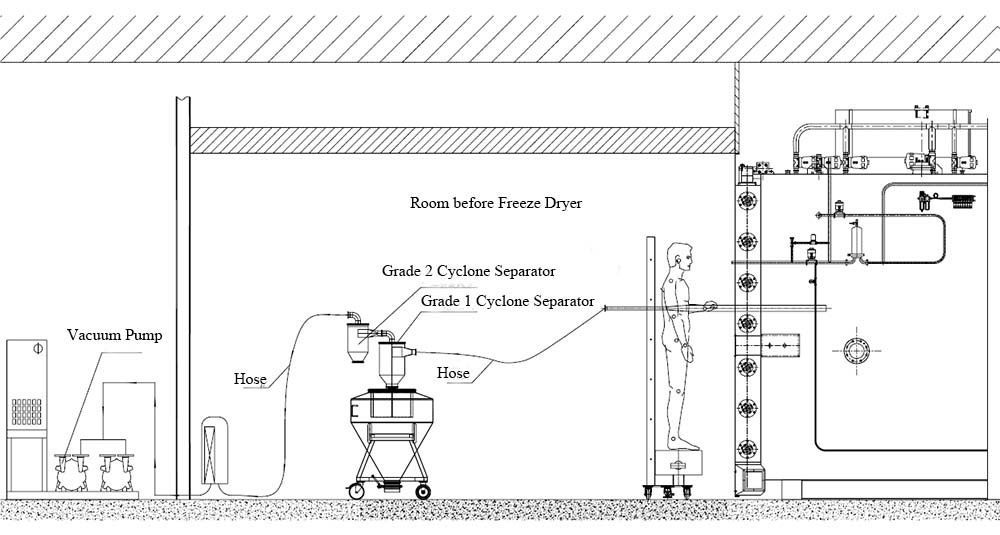

Vacuum Unloading System

The unloading system adopts auxiliary manual or automatic vacuum unloading system to increase efficiency and decrease the risk of contamination and moisture.

Manual Unloading System

Automatic Unloading System